- NEWS

- Is Steel Harder Than Aluminum With 1 Question

Is Steel Harder Than Aluminum With 1 Question

When evaluating materials for construction and manufacturing, the comparison between steel and aluminum frequently arises, particularly regarding their hardness. The question “Is steel harder than aluminum?” is essential for professionals across various industries, from construction to automotive. To thoroughly answer this question, we must delve into the properties of both metals, their applications, and the implications of their hardness in real-world uses.

Understanding Hardness

Hardness is a measure of a material's resistance to deformation, scratching, or indentation. It’s typically measured using various scales, with the Brinell and Rockwell scales being popular choices. Steel, primarily composed of iron and carbon, exhibits a wide range of hardness levels depending on its composition and treatment. This variability makes steel a versatile material, often hardened through processes like quenching or tempering.

In contrast, aluminum is a softer metal, with pure aluminum having a hardness of around 15 on the Brinell scale. However, aluminum alloys, which contain elements like copper, magnesium, or silicon, can achieve higher hardness levels. Generally, aluminum alloys range from 20 to 40 on the Brinell scale, but they still do not surpass the hardness of steel.

Comparative Hardness

In most scenarios, steel is indeed harder than aluminum. For example, structural steel used in buildings can reach hardness values above 120, showcasing its strength and durability. This is why steel is often favored for heavy load-bearing applications. On the other hand, aluminum’s lower hardness makes it more susceptible to scratches and dents, which is a crucial consideration in certain applications.

However, hardness is not the only factor influencing material choice. While steel’s hardness provides benefits in terms of strength, it can also lead to brittleness under certain conditions. Aluminum, being more malleable, can absorb impacts better without fracturing, making it an appealing option for specific uses.

A Focus on Decking and Roofing

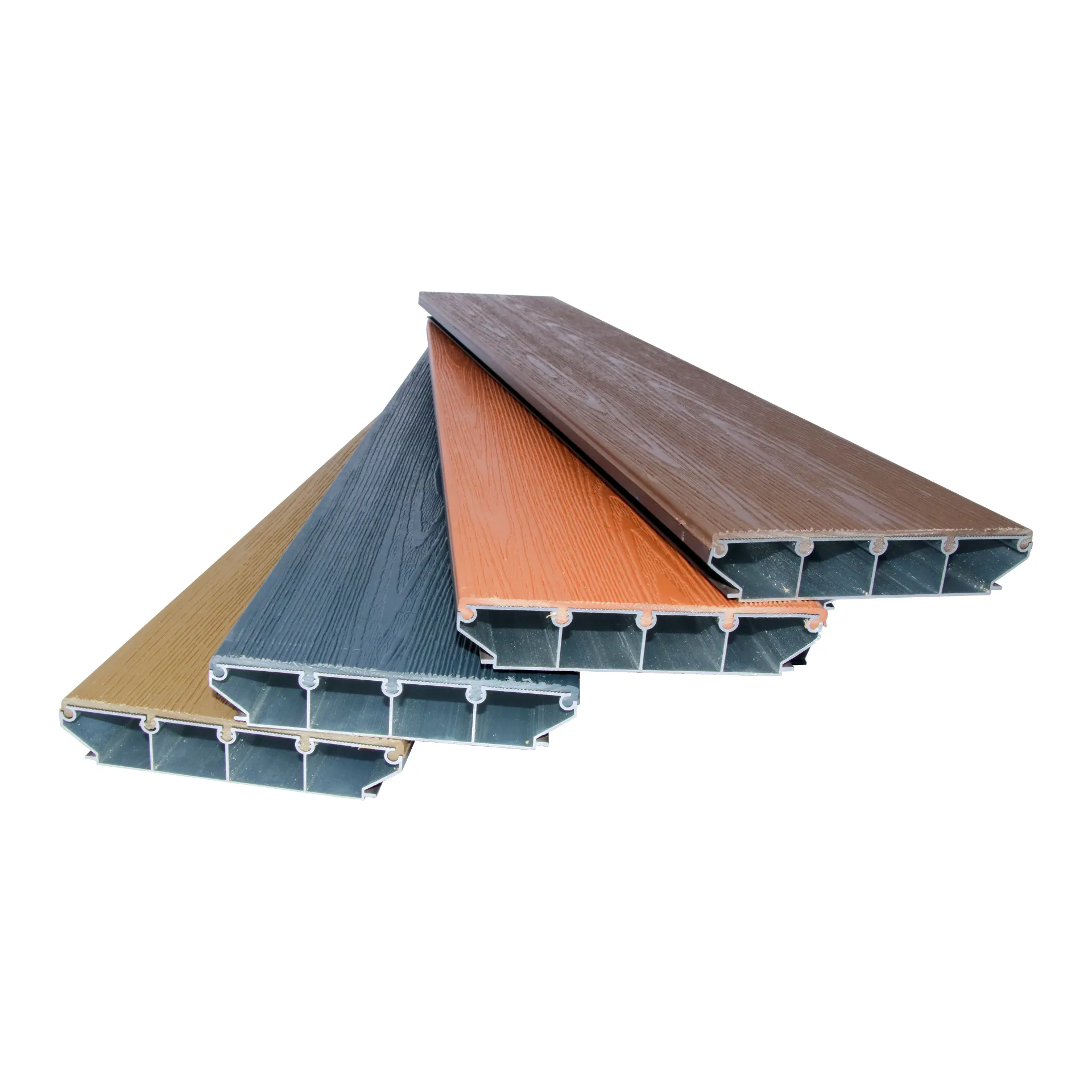

Aluminum’s properties, particularly its lightweight and corrosion resistance, make it an ideal choice for various applications, including aluminum decking. Aluminum decking is rapidly gaining popularity due to its durability and low maintenance requirements. Unlike wood, it will not warp, splinter, or rot, and its resistance to rust makes it perfect for outdoor environments. This application showcases how aluminum's unique characteristics can compensate for its lower hardness compared to steel.

In the automotive industry, aluminum car roofs are becoming increasingly common. In car manufacturing, particularly for roofs, allows for significant weight reduction, which enhances fuel efficiency. While a steel roof may provide greater hardness and strength, the benefits of lighter materials are pushing manufacturers toward aluminum. This trend highlights the shift towards prioritizing efficiency and safety in vehicle design.

Furthermore, aluminum patio roofs offer a practical solution for outdoor spaces. These roofs provide shelter while being lightweight and easy to install. Their resistance to weathering ensures that they maintain their appearance and functionality over time, making them an attractive option for homeowners. Although a steel patio roof might offer superior hardness, the benefits of aluminum in terms of ease of installation and maintenance often outweigh its drawbacks.

Conclusion

In conclusion, while steel is generally harder than aluminum, the choice between these two materials extends beyond just hardness. Steel’s strength and durability make it suitable for heavy-duty applications, while aluminum’s lightweight nature and corrosion resistance offer significant advantages in specific situations like aluminum decking, aluminum car roofs, and aluminum patio roofs. Each material serves its purpose effectively, and understanding their properties helps in making informed choices for construction and manufacturing projects.

Ultimately, the inquiry about whether steel is harder than aluminum opens up a broader dialogue about material selection based on specific needs, performance requirements, and environmental considerations. In industries ranging from construction to automotive, both steel and aluminum play indispensable roles, each excelling in their respective domains. As technology evolves, the understanding of these materials will continue to grow, leading to innovative applications that maximize their strengths.

If you are interested in our aluminum profiles, please contact us for a free quotation.

-

Aluminum Solution:How Tall is a Standard Door?NewsMay.08,2025

-

How Much Should a Sunroom Cost?NewsApr.30,2025

-

Ultimate Stunning Gazebo Designs and PlansNewsApr.25,2025

-

How to Replace Window Glass in Aluminum FrameNewsApr.22,2025

-

What is a Solarium in an Apartment?NewsApr.18,2025

-

Ultimate Steel Carport Kits Do It YourselfNewsApr.16,2025

-

Landscaping Gazebo IdeasNewsApr.11,2025